Mineral processing is a critical component of the mining industry, where the efficient separation of valuable minerals from waste materials directly impacts profitability, resource recovery, and environmental sustainability. As industries demand higher-quality materials and more sustainable practices, innovative technologies like dry jigging are gaining momentum. Among the leading solutions in this area is the High-Performance KQT-C Dry Jigging Equipment, a tool designed to optimize the separation process while addressing key concerns related to water use, energy efficiency, and mineral recovery rates.

Industry Background and Market Demand

The global mineral processing market has experienced significant growth, driven by the increasing demand for high-quality minerals in industries such as construction, electronics, and energy. As resource extraction becomes more complex, there is a growing need for advanced technologies that can improve separation efficiency, minimize environmental impact, and reduce operational costs. Traditional wet-based methods of mineral separation, which rely on water to create density differences between materials, are not always sustainable. These techniques require large amounts of water, contributing to environmental concerns, particularly in water-scarce regions.

The rise in environmental regulations and the global push for sustainable mining practices have further fueled the demand for dry mineral processing technologies. The KQT-C Dry Jigging Equipment addresses these needs by providing a dry separation method that reduces water consumption and enhances efficiency, making it a highly sought-after solution for modern mineral processing.

Core Concept and Key Technology Explanation

The core technology behind the KQT-C Dry Jigging Equipment is based on dry jigging, a process that separates materials using air pulses instead of water. Dry jigging relies on differences in the density of materials to separate valuable minerals from waste. The system uses a vibrating bed and controlled air flow to induce vertical movement in the material being processed. Denser particles sink to the bottom, while lighter particles rise, allowing for precise separation without the need for water or chemicals.

The KQT-C system is designed to work efficiently in a range of mineral processing applications, including coal, iron ore, and rare earth element recovery. Dry jigging is particularly effective in cases where water-based methods are not ideal, such as with materials sensitive to water or in arid regions where water availability is limited.

Product Structure, Performance, Materials, and Manufacturing Process

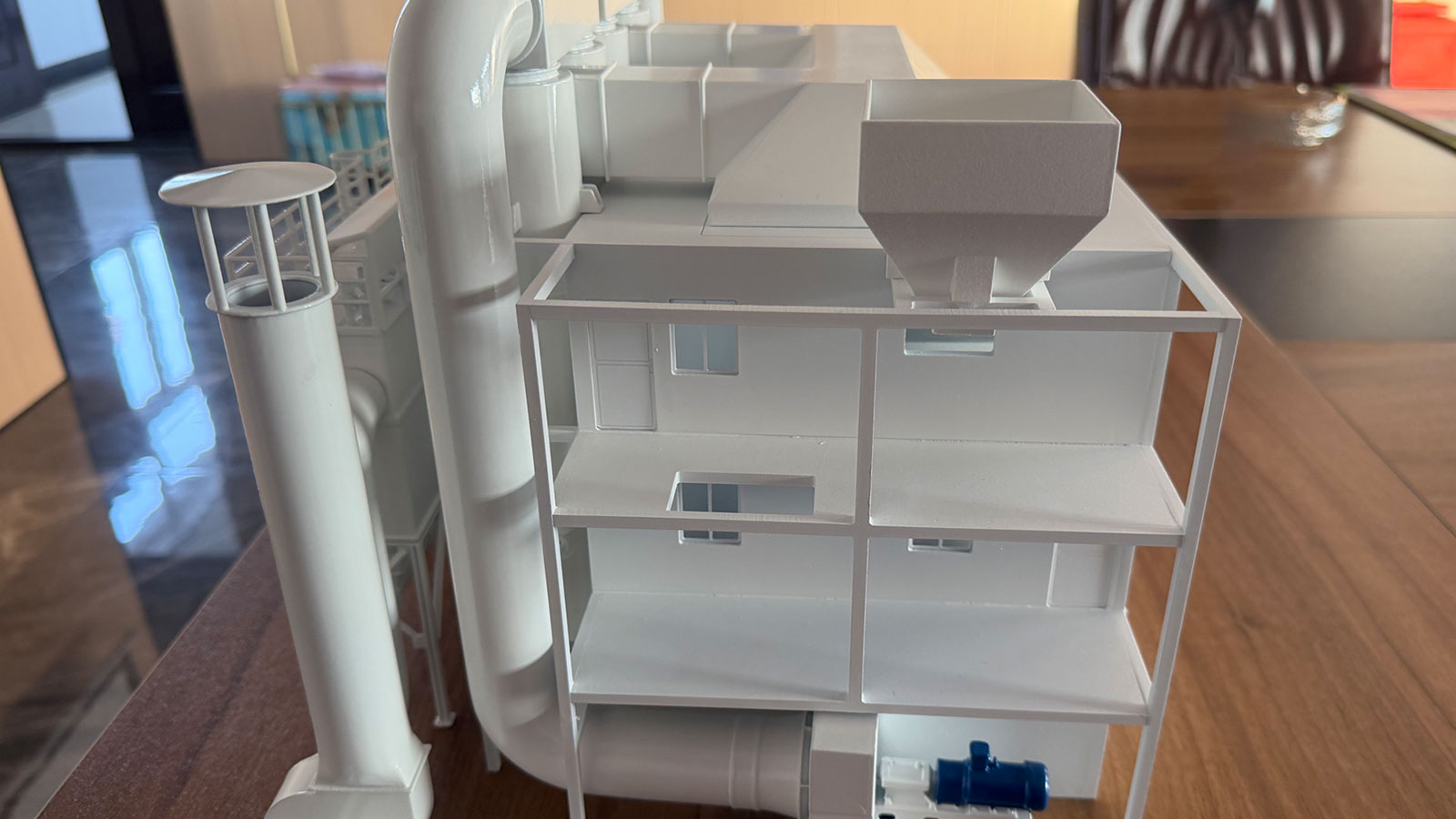

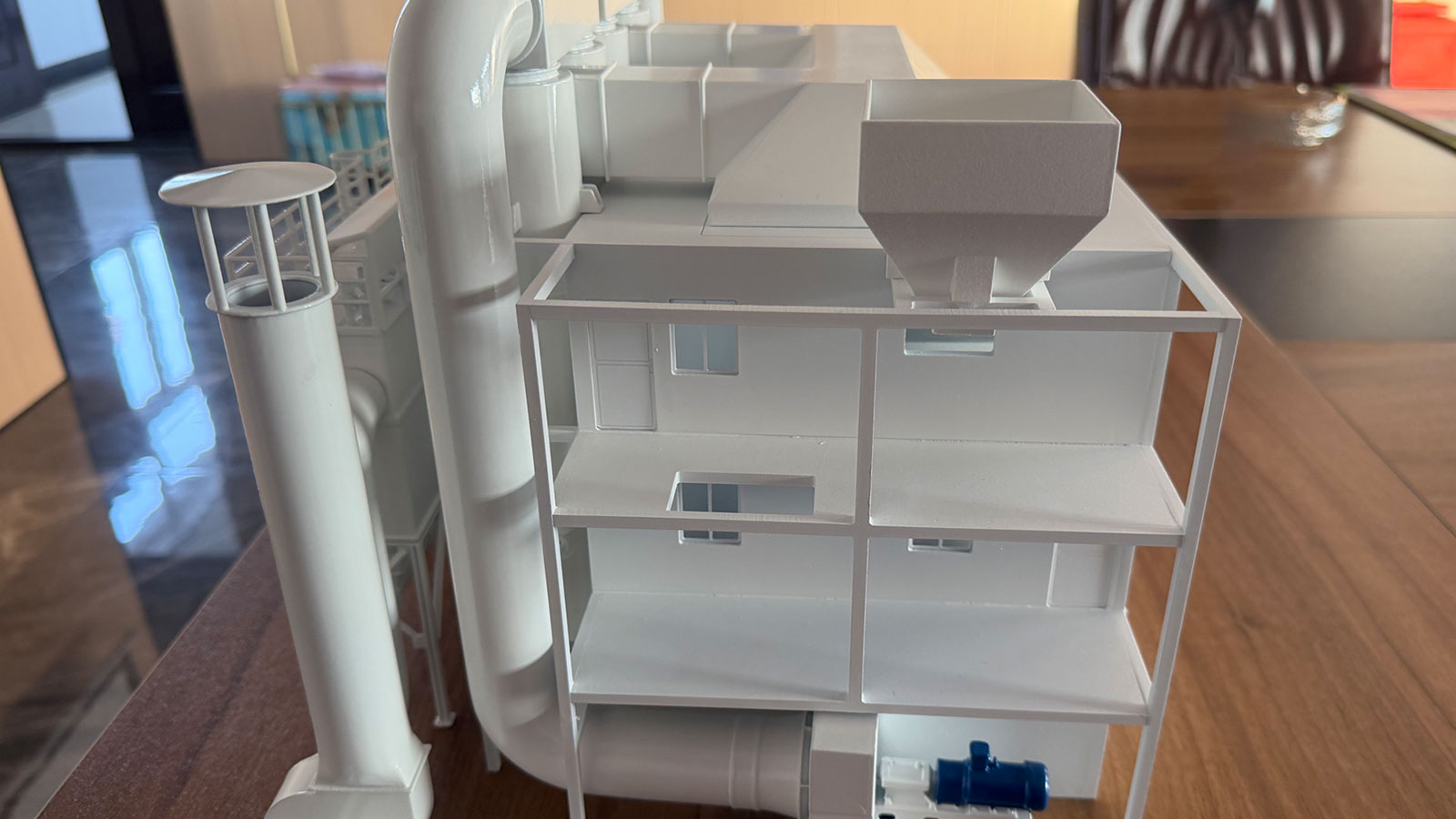

The KQT-C Dry Jigging Equipment is engineered with a robust structure to ensure long-lasting performance in demanding mining environments. It consists of several key components, including a vibrating bed, air pulse generation system, and a separation chamber. The vibrating bed is where the material is introduced and subjected to controlled vibrations that facilitate the separation process. The air pulse generation system delivers the precise airflow needed to create the density differences between particles. The separation chamber is where the sorted material is collected.

The equipment is designed for ease of operation and can be integrated into existing mineral processing plants. The materials used in constructing the KQT-C system are selected for their durability and resistance to wear. Components like the vibrating bed and air pulse system are designed to withstand the harsh conditions of continuous use in mining operations. The equipment's design ensures minimal maintenance downtime and long-term reliability, which is critical in high-demand industrial settings.

Manufacturing the KQT-C Dry Jigging system involves advanced engineering techniques, including precision fabrication and quality control processes. The system is built to meet rigorous performance standards, ensuring it can handle the continuous stresses involved in mineral processing.

Key Factors Affecting Quality and Performance

The performance of dry jigging equipment like the KQT-C system depends on several critical factors:

Airflow Control: The precise control of airflow is essential for efficient separation. Variations in air pressure can impact the separation process, making it crucial to maintain consistent airflow across the vibrating bed.

Vibration Frequency: The frequency and amplitude of the vibrations in the bed must be optimized to suit the type of material being processed. Incorrect vibration settings can result in poor separation and reduced recovery rates.

Material Characteristics: The physical properties of the material, such as density, shape, and particle size, significantly impact the effectiveness of the dry jigging process. The KQT-C system is designed to handle a wide variety of materials, but each material may require specific settings for optimal separation.

Operational Parameters: Variables such as the speed of operation, bed angle, and air pressure must be fine-tuned for each mineral type. Regular calibration ensures that the system remains efficient and effective in different processing conditions.

Supply Chain and Vendor Selection Criteria

When selecting a supplier for dry jigging equipment, several factors should be considered:

Reliability and Reputation: Suppliers with a proven track record in providing high-quality Mineral Processing Equipment are crucial for ensuring consistent performance. Manufacturers with positive customer reviews, industry certifications, and demonstrated expertise are preferable.

Customization Capabilities: Since mineral processing needs vary widely, it’s essential to select a supplier that offers customizable solutions tailored to specific applications. The ability to adjust operational parameters such as vibration frequency and airflow makes the KQT-C system adaptable to various mineral types.

After-Sales Support: Comprehensive after-sales support, including training, maintenance, and spare parts availability, is vital for minimizing downtime and ensuring long-term system performance.

Cost-Effectiveness: Beyond the initial purchase price, the total cost of ownership should be considered. This includes maintenance, operational energy costs, and the lifespan of the equipment. A cost-effective solution maximizes ROI while maintaining high levels of performance.

Common Issues and Industry Pain Points

Despite its many benefits, the use of dry jigging technology can present certain challenges. Common issues faced by operators include:

Material Inconsistency: Variations in the material’s properties can lead to inconsistent separation. Operators may need to adjust the system’s settings frequently to account for changes in feed material.

Wear and Tear: The vibrating components of the dry jigging system are subject to significant mechanical stress, leading to wear over time. Regular maintenance and component replacement are necessary to maintain efficiency and extend the equipment’s lifespan.

Energy Consumption: While dry jigging is more energy-efficient than many wet-based techniques, the equipment still requires a significant amount of power for vibration and airflow. Optimizing operational settings can help minimize energy consumption.

Applications and Use Cases

The KQT-C Dry Jigging Equipment is used in various mineral processing applications, particularly where water use needs to be minimized or where traditional wet methods are less effective. Key applications include:

Coal Processing: The KQT-C system is used to separate coal from impurities, improving the quality and value of the final product.

Iron Ore Separation: Dry jigging is effective in separating iron ore from waste materials, enhancing recovery rates and ensuring the extraction of high-purity ore.

Rare Earth Element Recovery: The system can be used to extract rare earth elements, which are vital in electronics, renewable energy, and other advanced industries.

Trends and Future Directions

The future of mineral processing, especially in the context of dry jigging, is heavily influenced by trends in sustainability, automation, and process optimization. With growing environmental concerns, technologies like dry jigging are becoming increasingly important for reducing water consumption and minimizing waste. Furthermore, the integration of smart sensors, machine learning, and automation will enhance the adaptability and efficiency of dry jigging systems, allowing for real-time adjustments and continuous performance optimization.

As mining operations continue to scale, the demand for energy-efficient, eco-friendly, and cost-effective solutions like the KQT-C Dry Jigging Equipment is expected to grow. These technologies will play a pivotal role in meeting both industry demands and environmental goals.

FAQ (Frequently Asked Questions)

Q1: How does dry jigging compare to traditional wet jigging?

Dry jigging offers significant advantages in water conservation and environmental impact. Unlike wet jigging, which requires large amounts of water, dry jigging uses air pulses to achieve the same high level of separation, making it ideal for regions with water scarcity or regulatory restrictions on water use.

Q2: What types of minerals can be processed using the KQT-C Dry Jigging Equipment?

The KQT-C system is versatile and can process a wide range of materials, including coal, iron ore, rare earth elements, and other minerals where density-based separation is required.

Q3: Is the KQT-C Dry Jigging system customizable?

Yes, the system can be customized to meet specific processing requirements. Adjustments to airflow, vibration frequency, and operational parameters ensure that the KQT-C equipment performs optimally for different materials and conditions.

Whatsapp

Whatsapp Teléfono

Teléfono